Matchless Info About How To Build With Fiberglass

Epoxy resin mixing, mixing micro filler and cotton flox.

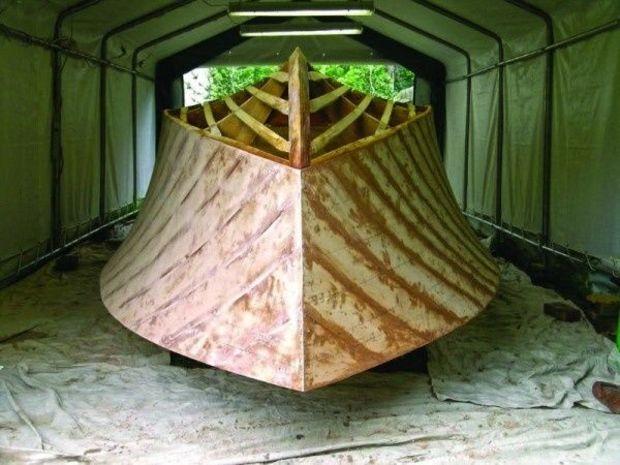

How to build with fiberglass. How to build a fiberglass boat: When building with a male mold, fiberglass fabric is laid over the mold’s exterior surface and is then saturated, or wet out, with liquid resin that has just been catalyzed. Fiberglass the price of fiberglass pools is about $46,000 on average.

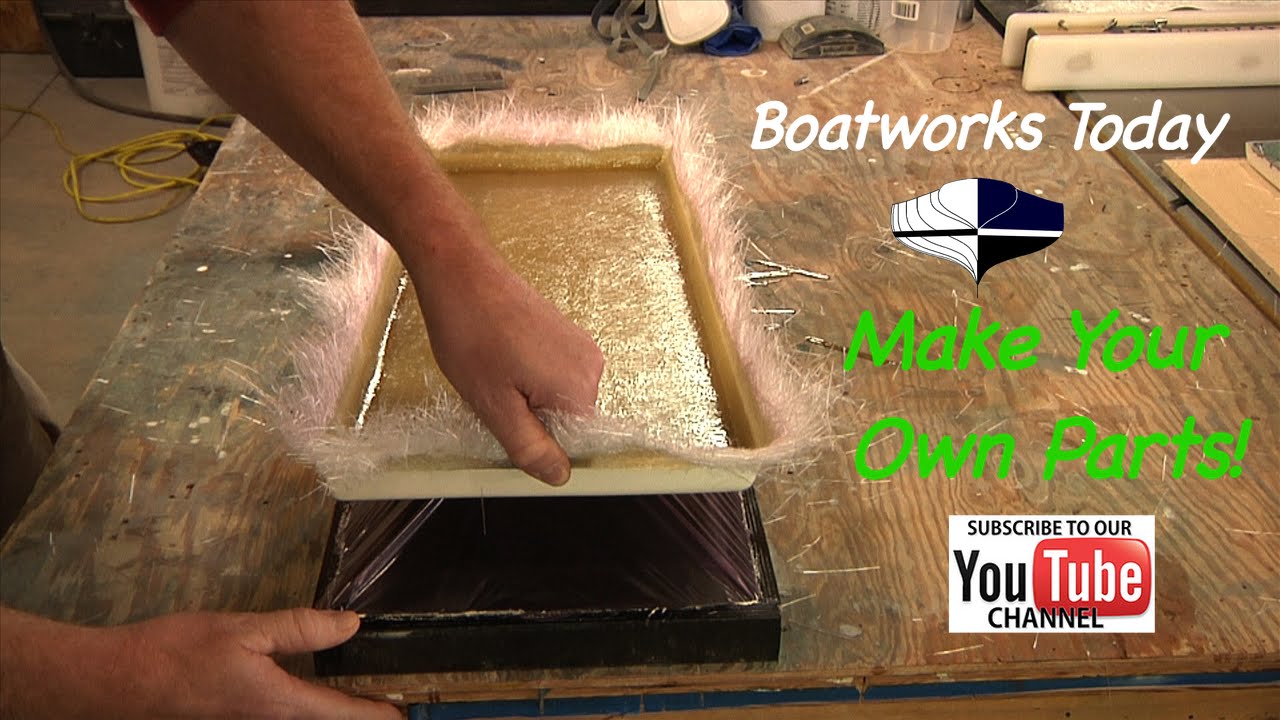

The mold is then filled with a filler material,. This helps prevent print through (when the fabric weave can be seen. The ultimate guide choose the right boat plans.

The next step is to add the fiberglass fabric. A layer of fiberglass mat should be used as the first layer. You can also use spray foam.

Fiberglass has a robust material for propmaking, aquatic sports, boating, surfing, artmaking.really everything! It is okay for the fiberglass to extend beyond the watercraft’s edges because you. Balancing epoxy resin and hardeners.

Fiberglass boats are made using a process known as extrusion, where the material is heated to a high temperature and then extruded into a mold. Next, the fiberglass cloth is cut and laid over the mold, followed by the resin. Building your own boat can be a rewarding experience, but it’s important to choose the.

The first step is to create a strong and sturdy mold that will be used to shape the canoe. Once the resin has cured,.